How can we believe that they can produce high-end handmade mattresses without even having their own original factory?

When it comes to customization, we have to mention customized production, and all of this requires the establishment of a factory with its own source for production and manufacturing, otherwise everything is in vain.

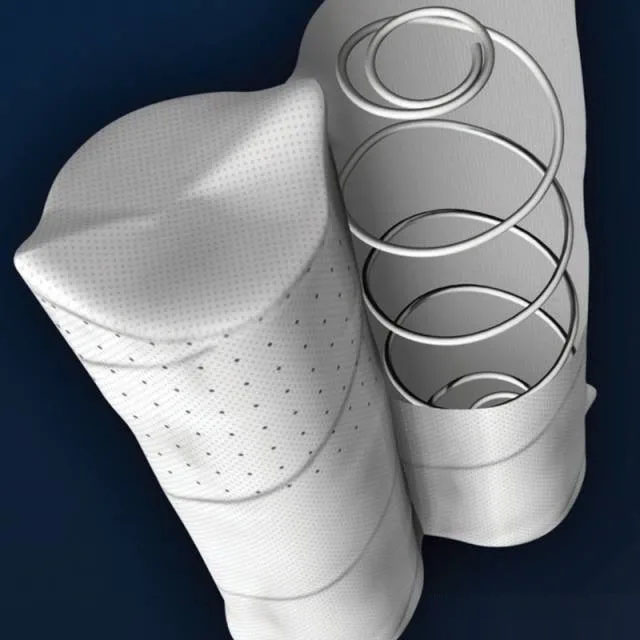

Hand sewn independent bag spring

When it comes to handmade mattresses, it must be mentioned that the independent bag springs made purely by hand, from the cotton and linen cloth bags wrapped on the outside to the built-in spring steel wires, are all based on the configuration of large brand handmade mattresses, striving to achieve quality fitting and replacement. Springs are all wrapped with steel wires, so the quality of the spring directly depends on the quality of the raw material steel wire.

Carbon, sulfur, manganese, phosphorus, and silicon are the most important and basic elements in steel. The content of these five elements directly affects the performance and quality of metals, among which carbon and sulfur are important elements in determining the specifications and quality of steel products. At present, Baosteel in Shanghai, Xingcheng Special Steel in Jiangyin, Shagang in Zhangjiagang, and Zhongtian Steel are all good steel mills in China. Steel with better quality has lower sulfur and carbon content, resulting in relatively higher costs.

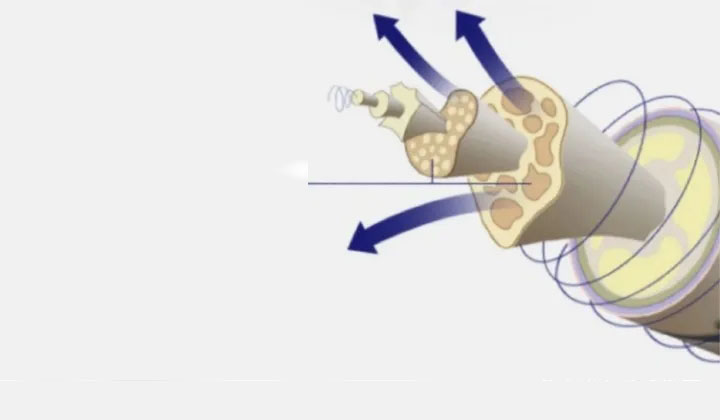

Our independent bag springs are made of high manganese carbon steel as the raw material, making the support very strong and durable. The spring warranty starts at 25 years, which is rare in the market. Most mattresses have a spring warranty period of only 10 years. After discussing the raw materials of springs, let's talk about the various parameters of springs. Our handmade mattress springs are Tianxuan three-stage induction springs up to 17 centimeters high, with an effective spiral of 12 turns!

The three-stage force visible to the naked eye is divided into upper, middle, and lower three-stage support forces. The spring bed core is designed with an effective spiral lift of 12 turns and adopts a segmented induction force. The upper end of the 4-stage spiral provides soft and comfortable support, while the middle end of the 4-stage spiral provides standard support when sensing body gravity. The end is set as gravity support, Provide strong support for heavy weight individuals when subjected to pressure. Segmented springs can sensitively sense different gravity pressures and provide appropriate support for different parts of the body, thereby improving the comfort of the mattress.

The wire diameter is 2.3mm, and it should be noted that the support spring wire diameter of popular mattresses on the market is less than 1.8mm! Each mattress undergoes over 100000 Cornell impact resilience tests before leaving the factory, and the edges of the bed are reinforced with coarse steel, so regardless of the weight of the person, they can feel strong support and comfortable wrapping.

After discussing the performance, let's talk about the process. Unlike the independent bag spring configuration for mass production and glue spraying on the assembly line, our handmade mattresses are all handmade, not just sewn on the outside, but each independent bag spring inside is manually bagged, with one spring for each cloth bag, and then sewn and connected by hand.

Made of cotton and linen cloth bags, handcrafted in series, without a single drop of glue, and the spring wire is also made by manual bagging. The components of cotton and linen fabrics include cotton cellulose and linen cellulose, and their advantages are also very obvious:

Good breathability and sweat permeability: Cotton and linen cloth can absorb sweat and micro sweat on the human skin, with a breathable and sweat absorbing effect. It is warm in winter and cool in summer, suitable for close fitting use.

Comfortable, itching relieving, skin friendly: Cotton and linen fabric has an acidic pH value and is non irritating to the skin.

Anti static: Cotton linen fabric is sewn with pure cotton and does not carry free charges. The cotton fibers are not easily deformed, do not pilling, and are very durable and wear-resistant.

Natural and environmentally friendly: From planting to hand weaving into fabric, without the use of pesticides and chemical dyes, textiles do not contain heavy metal ions such as formaldehyde and azo, making them very natural and environmentally friendly. As a family heirloom, it is not a problem to pass on to the next generation.

Pure natural rare filling material:

After discussing the core support springs, let's now introduce the filling materials that determine comfort. Horsetail hair and wool, two pure natural materials, are commonly used in handmade mattresses and are also very precious. Horsetail hair refers to the long fibers of hair on a horse's tail, characterized by long fibers, strong tensile strength, wear and moisture resistance, ventilation, elasticity, and not easy to break,it is known as "black gold".

In order to provide better support and a more comfortable sleeping experience, we have chosen 30-38 centimeters as the filling material for the core part of the horsetail hair.

The collected horsetail hair cannot be used directly and needs to undergo multiple manual treatments before it can finally be placed in our mattress. Firstly, they need to be steamed at high temperatures and cleaned with environmentally friendly detergents to achieve the screening effect of filtering impurities and removing odors; Then twist them into a rope like Fried Dough Twists, and then heat and dry them to keep the curl attribute stored; The third step is high-temperature and high-pressure sterilization treatment, making it less prone to bacterial growth and more natural and environmentally friendly.

And this series of processing is completed purely manually by the workers, without the use of any chemical additives. It is very time-consuming and labor-intensive, and the final processed curly horsetail hair needs to be left for a period of time before being spread manually and laid evenly.

The manual laying of horsetail hair is a huge amount of work! A handmade mattress 1.8m*2m needs to be filled with approximately 8 kg of horsetail hair, and millions of horsetail hair need to be spread evenly on top of the mattress, maintaining almost the same hand speed and repeating it continuously. It is necessary to align at various angles without any deviation, otherwise the final mattress will have inconsistent heights! This is also the reason why some mattress brands in some countries do not make handmade mattresses. Apart from the high cost, laying horsetail hair cannot be achieved by machines and must be laid manually and sewn by workers. The production capability is low and the cost is high,so the price cannot come down.

Each horsetail hair is composed of gaps and voids in the original fibers, forming a miniature scaly vacuum tube shape, and the entire mattress is like a microcirculation regulation system.

And the types of horsetail hair used in different positions are also different. For example, the soft and resilient horsetail hair used on the support removable top pad,it can make the mattress more wrapped and comfortable;The main body of the mattress is made of the longest and toughest part of horsetail hair, which can make the mattress more elastic and supportive.

It will take at least about 2 weeks to process and lay the horsetail hair. Only handmade mattresses made in this way can be stronger and more elastic. Each curled hair is a miniature spring that can provide more delicate support for the body. And there is almost no odor, and the sleeping sensation is more comfortable.

After talking about "Black Gold" horsetail hair, let's talk about "Diamond Fiber" cashmere. The cashmere used in our handmade mattresses is Kashmiri cashmere with outstanding quality among cashmere. Collecting only a thin layer of fine wool from the back of goats is extremely rare, hence it is known as "Soft Gold" and "Diamond Fiber". Its constant temperature effect is 8 times that of ordinary wool, with characteristics of lightness, flexibility, and delicacy, far exceeding the warmth and elasticity of other wool, making it very comfortable to sleep in warm winter and cool summer.

As mentioned in the mattress configuration: the stacking order of materials on a mattress has a direct impact on its sleeping sensation. Due to its characteristics, horsetail hair cannot be directly laid between the fabric quilting layer and the spring, so a wool cotton pad is needed to wrap the ponytail hair, absorb moisture and breathe air.

We adopt a 40% Australia wool and 60% cotton needle punched blend layer to wrap the horsetail hair, just like a furry thousand layers. Due to the fact that wool and horsetail hair can isolate moisture, cotton can expel excess heat, making the mattress breathable and moisture wicking, and people will not feel stuffy or damp lying on top. The combination of wool and cotton can also retain the characteristics of horsetail hair to the greatest extent, making the surface of the mattress soft and fitting, and dispersing body strength.

Luxury and comfortable imported fabrics

We are pursuing the same sleeping sensation as Europe's top handmade mattresses, so in addition to horsetail hair, the fabric is also imported fabric Bekaert that is the same as the big brands. As a renowned fabric manufacturer in the mattress industry, Bekaert Textile Group, headquartered in Belgium, is one of the world's largest manufacturers of mattress fabrics, sandbags, and curtain fabrics. With over 100 years of corporate development history, it is also a leader in global mattress fabrics. The biggest feature is comfort, breathability, and texture. Famous Armani suits and Andemar sportswear use Bekaert fabric, and well-known mattress brands such as 3S1K also use Bekaert fabric.

Our handmade mattress fabric consists of six sides, all of which are made of Bekaert Kashmir silk fabric. We carefully select high-end natural fibers such as cashmere and silk, which are made from precious natural silk. Through the special weaving process of Bekaert Company, it achieves international standards for wear resistance, breathability, and flame retardancy while maintaining a lightweight and soft body feel, as well as moisture and heat regulation performance. Warm in winter and cool in summer, flame retardant and mite resistant, with a very smooth and delicate feel, highlighting its luxurious handmade texture.

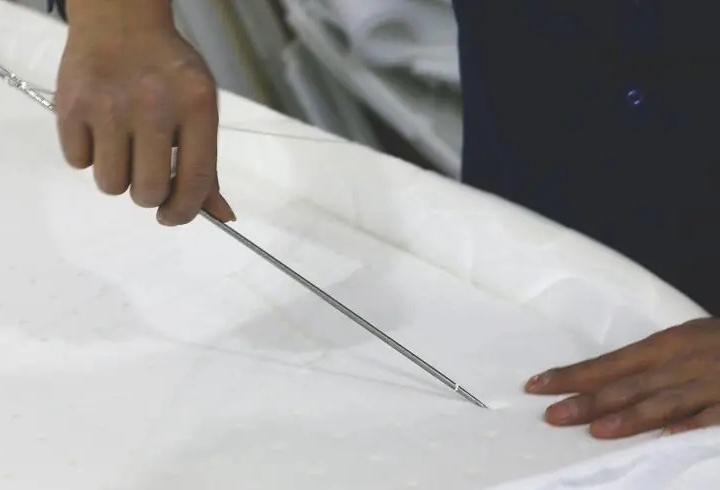

Handmade buckle with double-sided penetration, purely handmade

The most challenging aspect of handcrafted mattresses is their technique and endurance, as well as the final production process of handcrafted mattresses, which involves manual buckles. Handmade zippers also rely on pure manual labor. The exquisite zippers are threaded through special long nails to penetrate the fabric quilting layer, filling material layer, and manual spring layer of the mattress structure. This means that the mattress is penetrated from top to bottom on both sides, and the softness and hardness of the mattress are adjusted by the tightness of the zippers.

Handmade buckle technology has been passed down for hundreds of years and is a very ancient and traditional mattress material fixation technology, which is very environmentally friendly and healthy. The entire process is manually fixed without using a single drop of glue, only seen in pure handmade mattresses. This technology cannot be achieved by a skilled craftsman without more than 10 years of experience in bed making, who is diligent in exercise and has strong arms.

In the Norrkoping factory, only a single digit teacher can make pure handmade zippered mattresses. Using the same process as the world machine brand, a mattress needs to use at least 30 buckles on the front to secure the mattress fabric, double-layer cashmere, wool cotton blend layer, horsetail hair, wool cushion layer, and linen bag spring. With so many mattress materials stacked layer by layer, all of them are manually tightened and fixed by experienced craftsmen. Each stitch should pass vertically through multiple layers of material as much as possible, reducing the deviation of the back pull buckle. This process greatly tests the master's manual strength, which is time-consuming and labor-intensive, and also cost about a week.

Handmade mattresses made using the ancient method of manual pulling and fastening process do not have a single drop of glue, so there is no pungent odor, and there is no need to worry about formaldehyde emissions exceeding the standard in the long-term use of the mattress. The entire process is completely handmade with zero glue, so after delivery to home, the packaging plastic film can be torn open for use directly.

Your size and materials can be selected freely according to your needs, which can meet your personalized preferences and needs better. This is also a major advantage of the source factory. Although it is not an international brand and there is no capital involved, what I just want to do is to put more effort into this small product of about 3 square meters, persist for ten years in providing refined services to help our friends choose and deliver, in order to ensure the long-term comfortable sleeping experience of the mattress.